JDMS,EMS

JDMS,EMSOrganic Light-Emitting Diode

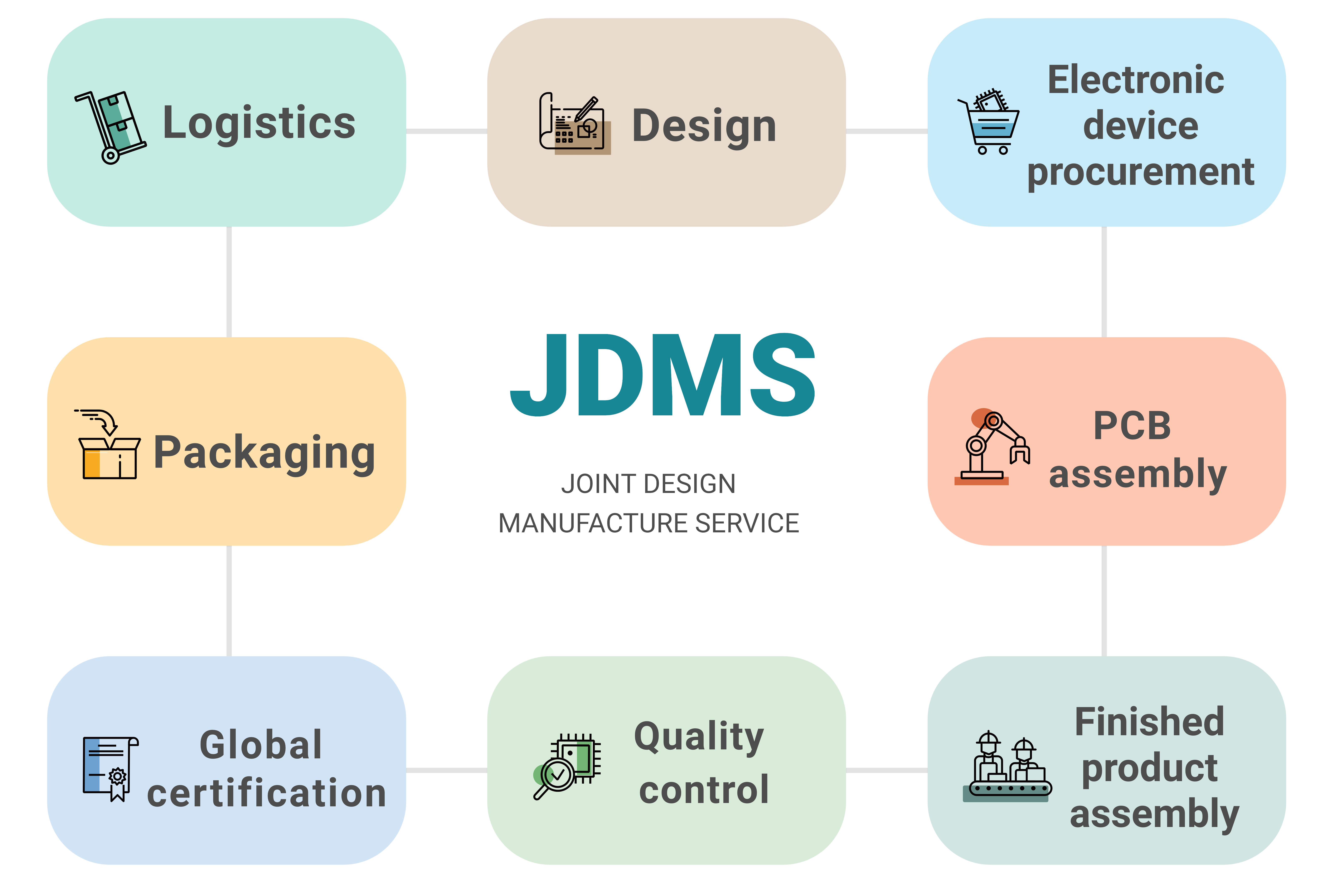

SINFER JDM (joint design manufacturer) services possess excellent design capabilities and a complete one-stop manufacturing system. We offer the best manufacturing and supply system.

SINFER offers the best manufacturing and supply chain and also works with customers on product design and manufacturing coupled with board, mechanical design, software design, manufacturing and validation to fully address customers’ expectations and requirements as well as the needs of various applications.

■Design

To lower costs, SINFER welcomes various proposals including product improvement or new product design.

・Mechanical design: Besides the design drawing, SINFER offers services from internal components procurement, form factor design, procurement to tooling.

・PCB design: Besides the circuit diagram, SINFER provides design services from board circuit, single-sided to multilayer PCB.

・Software design: SINFER provides design services including computer, microcomputer application system and hardware/software/firmware of communication interface.

■Electronic device procurement

With the experiences and achievements over the years, SINFER can procure alternatives from Japan or non-Japan (Taiwan, HK or China) manufacturers all over the world.

■PCB assembly

SINFER offers services of small board and precise machine assembly which need to be performed in the cleanroom.

●SMT Surface Mount Technology

SINFER possesses assembly machines from manufacturers including Juki, Yamaha, Sanyo, Panasonic and Siemens and is capable of manufacturing device types like BGA, CSP and 1005. Our processes can handle a pitch as small as 12mil (0.305mm). The thickness of solder paste is tested to ensure soldering quality. SINFER also applies X-ray analyzers and AOI inspection devices.

●COB (Chip On Board) assembly

For wire and die bonding processes, it is very important to solve issues caused by humidity, foreign object, static and temperature change. The COB line is required to be performed at a cleanroom grade and SINFER owns a FSE 209E 10K and 100K certified cleanroom.

●Assembly lines

Assembly lines are adjusted and designed according to product type, order quantity, quality requirements and other requests.

■Finished product assembly

Provide diversified and cell production lines based on product type, order quantity and quality requirement.

■Quality control

All processes are systematically managed, from incoming quality control, input process quality control and outgoing quality control. SINFER also maintains a perfect quality system conforming to domestic and international regulations and standards.

●Quality management

SINFER builds a reliable and trustworthy relationship with customers through our quality management mechanism. We conduct the incoming inspection to make sure all components are good before starting manufacturing, no matter customer supplied components or components purchased by SINFER. We also possess hazardous materials analyzer for analysis of chemicals like lead or cadmium.

※SINFER can also perform outgoing inspection and provide the records per customers’ requests. We also do reliability tests including burn-in test, environmental test, vibration test and drop test. SINFER is certified by ISO9001, ISO14001, ISO13485, ISO/TS16949, OHSAS18000 and ANSI/ESD S20.20-2007.

■Global certification application service

Our service range covers the certification, testing and inspection of electronic devices in Asia, USA and Europe. SINFER provides services from application to certification acquisition with designated labs based on different product types.

■Packaging

Products are packaged per customers’ requests.

■Logistics

After all processes are completed, finished products will be delivered to the place designated by the customer securely and quickly by contracted logistics companies.